PRODUCTS

Categories

Message

Brass sheet suppliers in the UK may also offer lead brass. Lead brass contains about 3% lead in its makeup and makes the brass easier to machine i.e. it becomes easier to rework and reform

If you have any questions, please feel free to contact us.

PRODUCT INTRODUCTION

Product Parameters

Leaded Brasses:

Used for their high machinability and atmospheric corrosion resistance. The machinability of brass is increased by the addition of lead because it acts as a microscopic chip breaker and tool lubricant. The leaded brasses are used for copper base screw machine material. The alloys have excellent machinability, good strength and corrosion resistance. Lead can be added to any brass to increase machinability and provide pressure tightness by sealing the shrinkage pores. There are low, medium and high leaded brasses, with lead contents up to 3.5%. The lead brasses are used for architectural hardware, general purpose screw machine parts, screws, valves, fittings, bearings and specialty fasteners.

Tin Brass:

Used for its increased corrosion resistance and somewhat higher strength than straight brass. This family of alloys is made with zinc contents ranging form 2 to 40% zinc, and 0.2 to 3.0% tin. Tin reduces susceptibility of the high zinc brass to dezincification. Dezincification is the selective leaching of zinc from the brass leaving a porous copper structure.

Chemistry Typical

Leaded Brass

COPPER TIN LEAD IRON ZINC PHOSPHORUS

C35000 60.0-63.0 0.8-2.0 0.15 max Balance

C35300 60.0-63.0 1.5-2.5 0.15 max Balance

Tin Brass

COPPER TIN LEAD IRON ZINC PHOSPHORUS

C42200 86.0-89.0 0.8-1.4 0.05 max 0.05 max Balance 0.35 max

C42500 87.0-90.0 1.5-3.0 0.05 max 0.05 max Balance 0.35 max

Physical Properties

Typical Density:

Leaded Brass: 0.306 lb/in3, 8.47 g/cm3

Tin Brass: 0.317 lb/in3, 8.78 g/cm3

Electrical Conductivity: (% IACS at 68° F 20°C, annealed):

Leaded Brass: 26%

Tin Brass: 28-31 %

Thermal Conductivity: BTU-in/hr-ft2-° F

At 68° F: 67 - 75

Mean Coefficient of Thermal Expansion: µin/in-° F 68 - 572 ° F: 10.2 - 11.3

Modulus of Elasticity: KSI

15 - 16 x 103 in tension

What is a Brass Sheet?

Brass sheet is an alloy consisting of 70% copper and 30% zinc. It is also known as yellow brass because of its vibrant gold colour.

Brass sheets have major applications in the architectural and hardware industry. It can be beaten into a thin brass sheet or rolled into a tubular shape. It’s possible to cut brass in different sizes and apply different finishes to each brass plate for a unique touch.

We have a 0.5mm brass sheet that comes in its natural form and a semi-bright finish.

Additionally, we also have the 0.9mm brass sheet and a 1.2mm brass sheet in both natural forms and semi-bright finishes.

We also provide brass sheets with reflective surfaces that are ideal for art installations and interior design. We have them in 1.5mm brass sheet, 2mm brass sheet, 3mm thick brass plate and 5mm brass plate dimensions. They come in a brightly polished or mirror polished format.

Brass sheet can take on many different appearances from distressed, brushed, hammer beaten and soft forms. You can also find different finishing options; mill finish, aged brass, bright, dull, mirror sheet, polished brass sheet and more.

Our Brass Sheets: Features to Expect

Brass has a lot of features that make it the ideal metal to use in domestic and industrial settings. Whether you are working with a polished brass sheet or a roll of brass, there are certain properties exclusive to the metal that makes them highly sought after.

Colour Variety

Brass sheets typically come in a myriad of colours depending on the levels of zinc and copper in them. They can appear as a reddish-gold metal or have a brighter gold colour to them.

Alternatively, it may appear silver-white or whisper grey. A higher percentage of copper yields a reddish tone while a higher percentage of zinc will produce a more silver hue.

Brass

TRANSPORTATION PACKAGING

ABOUT US

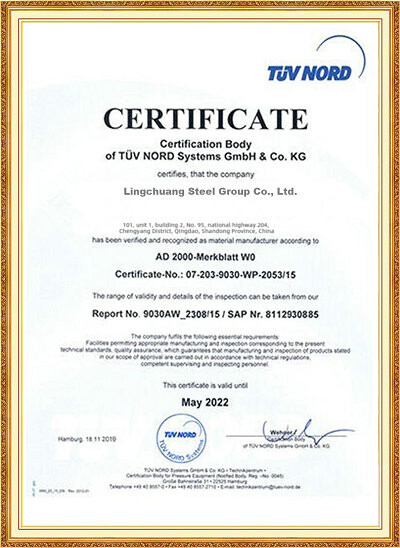

Lingchuang Steel Group Co., Ltd. is located in the beautiful coastal port city, Jinan, Shandong province, which is well-known with good reputation, high-quality products, strong strength and favorable price.

The Company has been engaged in the steel industry for over 15 years as well as rich steel experience in both the international market, and domestic market. The company has standard workshops and modern comprehensive equipment, providing a strong guarantee for high-quality products. The company has established strategic partnerships for import and export business with many famous enterprises. Now more than 10,000 tons of inventory and over 800 specifications in stock so that can ship timely to meet clients demand. These products are suitable for engineering, coal, textile, electric power and other industries.

OUR ADVANTAGE

Lingchuang Steel Group

we have perfect pre-sale consultation 7*24 hours online service, in-sale service, and after-sales service system to ensure customers in the whole procurement process of good experience.

01

Quality Promise

Provide return and exchange service for customers. Provide email and phone inquiries throughout the product transaction.

02

Deliver Faster

Arrange production immediately upon receipt of advance payment within 24 hours We can make transportation plan according to your requirements.

03

Competitive Price

We can provide competitive price, please contact us for quotation.

04

Third-Party Inspection

We offer third-party inspection for our products. It could be of client's choice or we arrange the internationally renowned agencies.

ONLINE MESSAGE

If you have any questions or comments, you can leave us a message and we will reply to you as soon as possible

RECOMMENDED PRODUCTS