PRODUCTS

Categories

Message

If you have any questions, please feel free to contact us.

PRODUCT INTRODUCTION

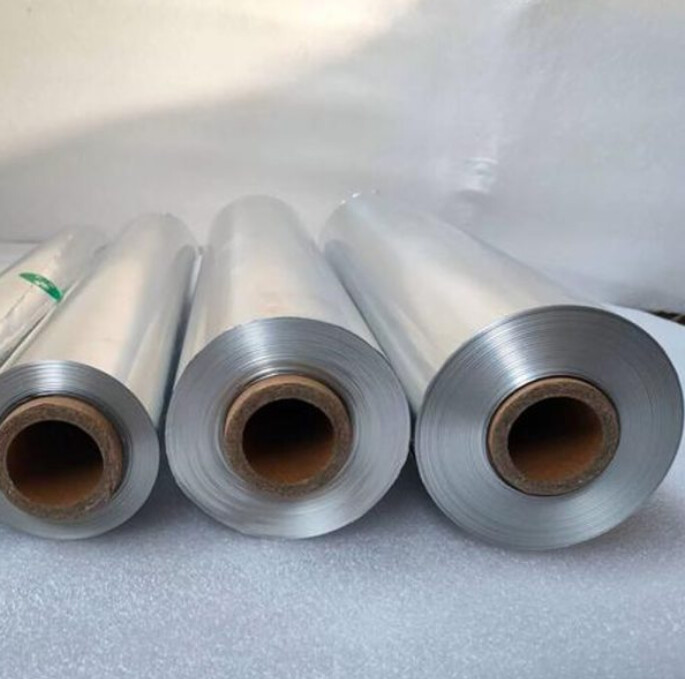

Aluminium Foil is a thin, flexible sheet of aluminium metal, typically 0.006 mm to 0.2 mm (0.0002″ to 0.0079″) in thickness, produced by rolling aluminium ingots into ultra-thin layers. Known for its excellent barrier properties, malleability, and heat conductivity, aluminium foil is widely used in packaging, insulation, and household applications. Its non-toxic, lightweight, and recyclable nature makes it indispensable across industries ranging from food preservation to aerospace.

Product Description

Key Alloy Properties:

1235/1050/1060: High purity (99.3%+ Al) for food packaging and electronics.

8011/8079: Iron and silicon additives for strength and heat resistance (e.g., pharmaceutical blister packs).

1100: Balanced formability and corrosion resistance for industrial uses.

Chemical Composition of Aluminum Foil (Common Alloys)

Aluminum foil is typically made from high-purity or alloyed aluminum, depending on its application. Below are typical compositions for popular foil alloys (values in weight %):

Notes:

1235/1050: High-purity aluminum (≥99% Al) for food packaging and electronics (excellent barrier properties).

8011/8079: Iron (Fe) and silicon (Si) improve strength and heat resistance (used in pharmaceutical and industrial foils).

1100: Balanced ductility and corrosion resistance for general-purpose applications.

Mechanical Properties of Aluminum Foil

Mechanical properties depend on alloy, temper, and thickness. Foil is often supplied in annealed (O) or hard (H18) tempers. Typical values include:

Key Definitions:

Tensile Strength: Maximum stress the foil can withstand before breaking.

Yield Strength: Stress at which permanent deformation begins.

Elongation: Measure of ductility (% stretch before fracture).

Temper:

O (Annealed): Soft, highly ductile (ideal for forming and wrapping).

H18 (Fully Hard): High strength but brittle (used for rigid packaging).

Factors Influencing Properties

- Alloying Elements:

High Purity (1235/1050): Excellent for food safety and electrical conductivity.

Fe/Si (8011/8079): Enhances strength and heat resistance for industrial uses.

- Thickness:

Thinner foils (e.g., 0.006mm) are more flexible but less durable.

Thicker foils (e.g., 0.2mm) offer better puncture resistance.

- Surface Treatment:

Lacquered/Coated: Adds anti-corrosion or non-stick properties.

Embossed: Improves rigidity and aesthetic appeal.

TRANSPORTATION PACKAGING

ABOUT US

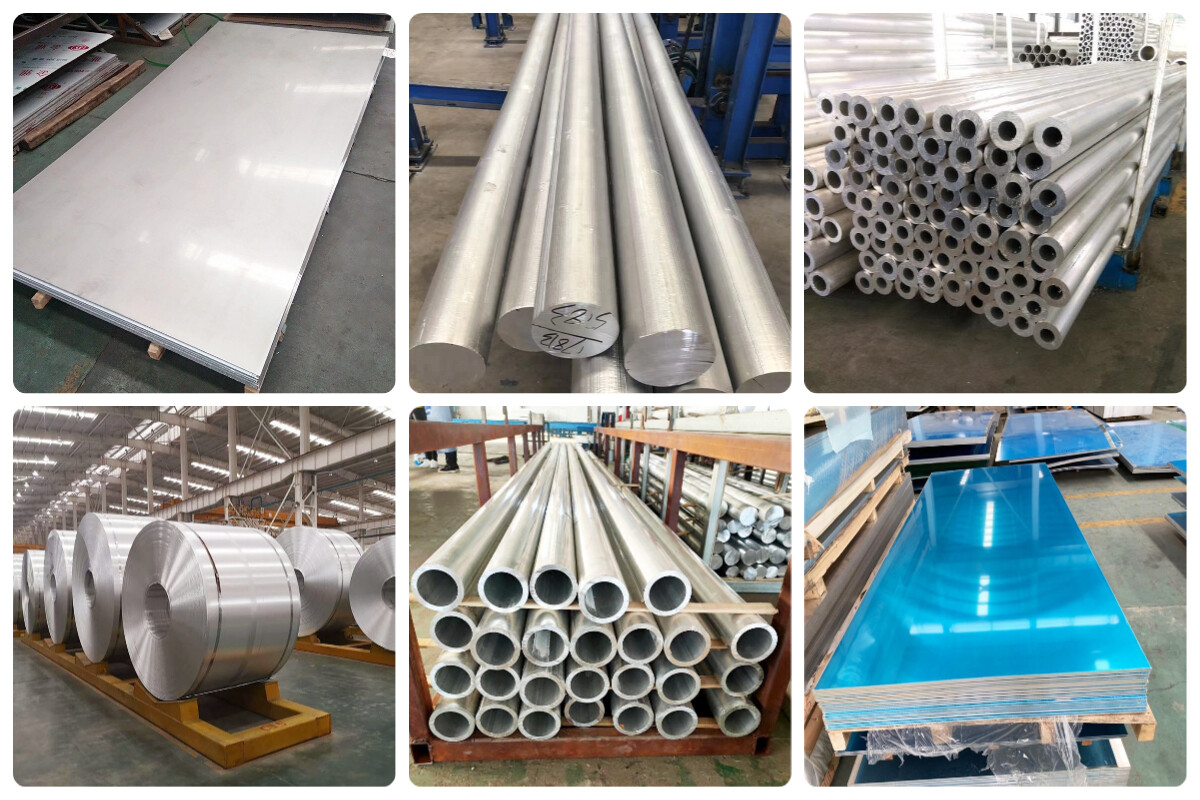

Lingchuang Steel Group Co., Ltd. is located in the beautiful coastal port city, Jinan, Shandong province, which is well-known with good reputation, high-quality products, strong strength and favorable price.

The Company has been engaged in the steel industry for over 15 years as well as rich steel experience in both the international market, and domestic market. The company has standard workshops and modern comprehensive equipment, providing a strong guarantee for high-quality products. The company has established strategic partnerships for import and export business with many famous enterprises. Now more than 10,000 tons of inventory and over 800 specifications in stock so that can ship timely to meet clients demand. These products are suitable for engineering, coal, textile, electric power and other industries.

OUR ADVANTAGE

Lingchuang Steel Group

we have perfect pre-sale consultation 7*24 hours online service, in-sale service, and after-sales service system to ensure customers in the whole procurement process of good experience.

01

Quality Promise

Provide return and exchange service for customers. Provide email and phone inquiries throughout the product transaction.

02

Deliver Faster

Arrange production immediately upon receipt of advance payment within 24 hours We can make transportation plan according to your requirements.

03

Competitive Price

We can provide competitive price, please contact us for quotation.

04

Third-Party Inspection

We offer third-party inspection for our products. It could be of client's choice or we arrange the internationally renowned agencies.

ONLINE MESSAGE

If you have any questions or comments, you can leave us a message and we will reply to you as soon as possible

RECOMMENDED PRODUCTS